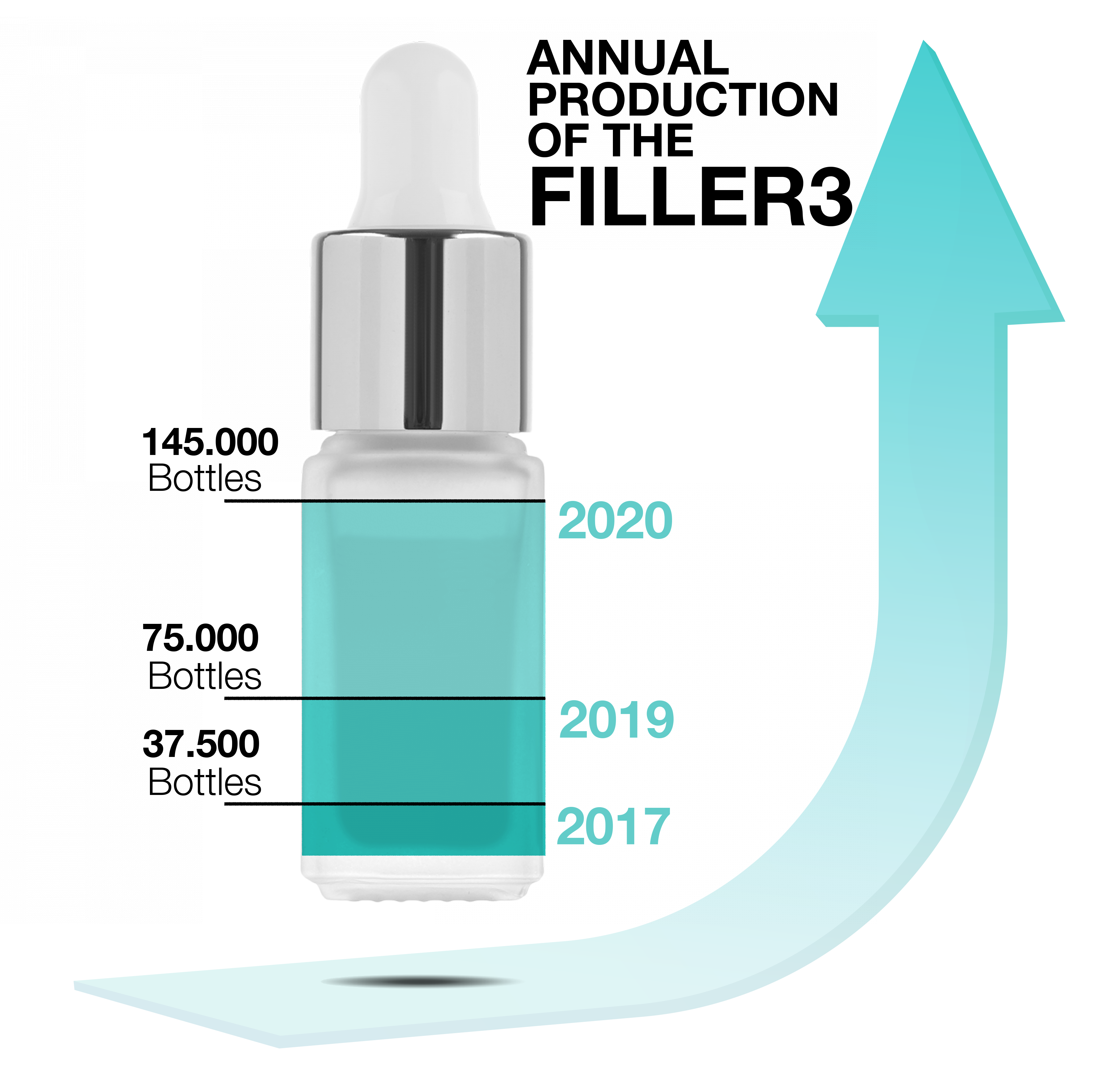

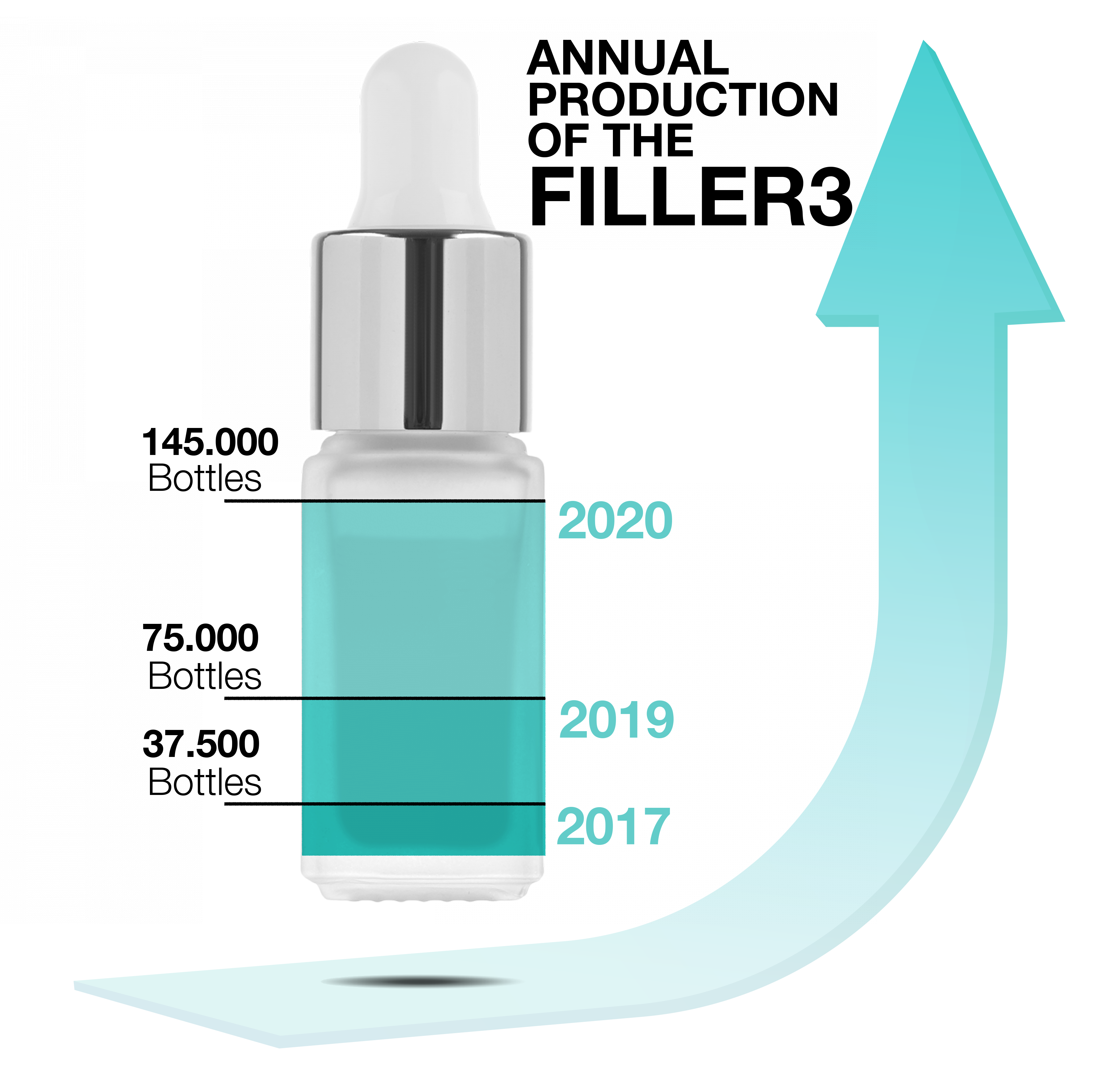

Our journey began years ago with minimal bulk productions that did not exceed a few hundred kilos per product. Over the years, the quality of our products has become known worldwide, even without great efforts in marketing activities. We have reached an extremely high international demand, and there are so many requests that we are currently oversubscribed.

For the success of the whole process, it is not enough to be a manufacturer. It is essential to find the right collaborations. A product not only depends on the individual's commitment but on a chain of mechanisms that must work together. All the companies involved under the "InLei® - Made in Italy Excellence" project have been carefully chosen, and they guarantee an even more qualified and efficient internal process.

Each raw material, each supplier, and each detail are carefully selected to keep our position at the top of the sector proudly. Our products have the GMP (Good Manufacturing Practices) certification. This means that they are created following a set of guidelines that ensure high quality, hygiene, and safety standards. These rules concern the production methods and the management of all operations, but they also refer to equipment, means, storage, and shipping.

We work with more than 50 different Italian companies with many years of experience.

To give some examples:

For the success of the whole process, it is not enough to be a manufacturer. It is essential to find the right collaborations. A product not only depends on the individual's commitment but on a chain of mechanisms that must work together. All the companies involved under the "InLei® - Made in Italy Excellence" project have been carefully chosen, and they guarantee an even more qualified and efficient internal process.

Each raw material, each supplier, and each detail are carefully selected to keep our position at the top of the sector proudly. Our products have the GMP (Good Manufacturing Practices) certification. This means that they are created following a set of guidelines that ensure high quality, hygiene, and safety standards. These rules concern the production methods and the management of all operations, but they also refer to equipment, means, storage, and shipping.

We work with more than 50 different Italian companies with many years of experience.

To give some examples:

We have seven reference laboratories for the creation of InLei® cosmetic products, each with 30 to 40 years of experience.

We collaborate with five independent laboratories that run all the analyses required by law to ensure each product's total safety.

Our brushes are created by a historic Italian brush factory with more than 40 years of experience.

The paper of our packagings comes from the best paper industries of the Italian market, with ISO, PEFC, FSC certifications that guarantee production in full respect of the environment.

InLei® shields come from a factory with almost 60 years of experience in the silicone products industry and a 120,000 square meter manufacturing unit. They are the leading experts in Europe, and with their help, we have created specific molds for our shields and tools.

The direct collaboration with a laboratory specialized in plastic and thermoplastic allows us to customize all the InLei® accessories and tools with our reference color.

We always look for the best raw material for the packaging of each product. That's why we are collaborating with several production companies, from aluminum to glass. This allows us to have a wide range of possibilities and always choose the best solution for convenience, safety, and innovation.

Our collaborations are only arranged with true experts and long-established Italian companies.

We check every single step of each product, which always follows a precise path:

LAB

MANUFACTURING

QUALITY CHECK

FILLING

ANALYSIS

PACKAGING

ASSEMBLY

DOCUMENTATION

MARKET SALES

The most significant advantage to our products is that they are made in Italy. This translates to the careful selection of raw materials from certified sources that must pass super strict quality controls.

If any of the above parameters are out of bounds, the product does not hit the market!

Our journey began years ago with minimal bulk productions that did not exceed a few hundred kilos per product. Over the years, the quality of our products has become known worldwide, even without great efforts in marketing activities. We have reached an extremely high international demand, and there are so many requests that we are currently oversubscribed.

For the success of the whole process, it is not enough to be a manufacturer. It is essential to find the right collaborations. A product not only depends on the individual's commitment but on a chain of mechanisms that must work together. All the companies involved under the "InLei® - Made in Italy Excellence" project have been carefully chosen, and they guarantee an even more qualified and efficient internal process.

Each raw material, each supplier, and each detail are carefully selected to keep our position at the top of the sector proudly. Our products have the GMP (Good Manufacturing Practices) certification. This means that they are created following a set of guidelines that ensure high quality, hygiene, and safety standards. These rules concern the production methods and the management of all operations, but they also refer to equipment, means, storage, and shipping.

We work with more than 50 different Italian companies with many years of experience.

To give some examples:

For the success of the whole process, it is not enough to be a manufacturer. It is essential to find the right collaborations. A product not only depends on the individual's commitment but on a chain of mechanisms that must work together. All the companies involved under the "InLei® - Made in Italy Excellence" project have been carefully chosen, and they guarantee an even more qualified and efficient internal process.

Each raw material, each supplier, and each detail are carefully selected to keep our position at the top of the sector proudly. Our products have the GMP (Good Manufacturing Practices) certification. This means that they are created following a set of guidelines that ensure high quality, hygiene, and safety standards. These rules concern the production methods and the management of all operations, but they also refer to equipment, means, storage, and shipping.

We work with more than 50 different Italian companies with many years of experience.

To give some examples:

We have seven reference laboratories for the creation of InLei® cosmetic products, each with 30 to 40 years of experience.

We collaborate with five independent laboratories that run all the analyses required by law to ensure each product's total safety.

Our brushes are created by a historic Italian brush factory with more than 40 years of experience.

The paper of our packagings comes from the best paper industries of the Italian market, with ISO, PEFC, FSC certifications that guarantee production in full respect of the environment.

InLei® shields come from a factory with almost 60 years of experience in the silicone products industry and a 120,000 square meter manufacturing unit. They are the leading experts in Europe, and with their help, we have created specific molds for our shields and tools.

The direct collaboration with a laboratory specialized in plastic and thermoplastic allows us to customize all the InLei® accessories and tools with our reference color.

We always look for the best raw material for the packaging of each product. That's why we are collaborating with several production companies, from aluminum to glass. This allows us to have a wide range of possibilities and always choose the best solution for convenience, safety, and innovation.

Our collaborations are only arranged with true experts and long-established Italian companies.

We check every single step of each product, which always follows a precise path:

LAB

MANUFACTURING

QUALITY CHECK

FILLING

ANALYSIS

PACKAGING

ASSEMBLY

DOCUMENTATION

MARKET SALES

The most significant advantage to our products is that they are made in Italy. This translates to the careful selection of raw materials from certified sources that must pass super strict quality controls.

If any of the above parameters are out of bounds, the product does not hit the market!